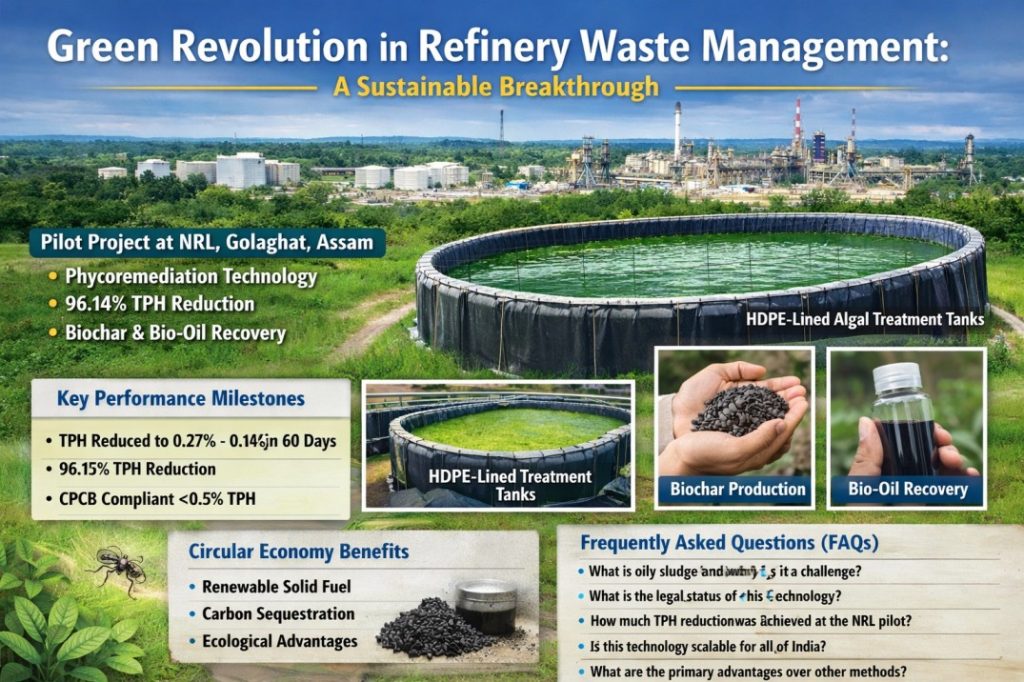

In the pursuit of Viksit Bharat 2047, the industrial sector is shifting from traditional waste disposal to circular waste valorization. A landmark pilot project at the Numaligarh Refinery Limited (NRL) in Golaghat, Assam, has demonstrated that the future of hazardous waste management lies in nature-based solutions.

DRIIV has pioneered Phycoremediation-based Technology for oily sludge treatment with an ecosystem partner, an eco-friendly breakthrough, and validated its technical and environmental feasibility in industrial waste management. This initiative exemplifies the power of strategic convergence by an S&T cluster by uniting government, industry, and technology partners to drive India’s transition toward sustainable and net-zero industrial practices. The positive outcomes, both in terms of hydrocarbon degradation and resource recovery, offer a scalable model for future implementation at industrial refineries and similar facilities. The success of this project lays the groundwork for broader adoption and policy integration of green remediation technologies in hazardous waste management frameworks.

The Technology: Harnessing the Power of Microalgae

Phycoremediation uses a specialized microalgal consortia to metabolize and break down complex hydrocarbons. Unlike traditional physico-chemical methods, this biological approach is carbon-negative, as microalgae consume carbon dioxide and release oxygen.

Key Performance Milestones

- Rapid Degradation: The technology reduced Total Petroleum Hydrocarbon (TPH) levels to 0.27% – 0.14% in under 60 days.

- High Efficiency: Validation by NABL-accredited laboratories confirmed a TPH reduction of 96.14%.

- Regulatory Compliance: The final treated sludge reached TPH levels well within the strict CPCB guideline of <0.5%.

- Sustainable Infrastructure: The site featured HDPE-lined treatment tanks and scaled-up algal cultures of 3000 L.

Circular Economy: Turning Waste into Wealth

The true revolution lies in the ability to convert hazardous waste into valuable by-products, ensuring a zero-waste cycle.

- Biochar Production: Pyrolyzing the residual algal biomass yields biochar (approx. 46% yield), which serves as a renewable solid fuel.

- Carbon Sequestration: One ton of biochar can lock away 2.2–3.0 tons of CO₂, qualifying for carbon credits.

- Bio-oil Recovery: The process generates bio-oil with a high calorific value, acting as a fossil fuel substitute.

- Ecological Benefits: Algal treatment naturally decreases mosquito larval populations, providing a significant socio-economic advantage to nearby areas.

Frequently Asked Questions (FAQs)

What is oily sludge and why is it a challenge?

It is a hazardous industrial waste (Schedule-1, Category 4.1) generated in refinery tank bottoms that is traditionally difficult to treat sustainably.

What is the legal status of this technology?

A successful patent has been published (202511016770 A) where Trinity International is the applicant and DRIIV is the co-applicant.

How much TPH reduction was achieved at the NRL pilot?

The pilot achieved a remarkable 96.14% reduction in TPH over a 60-day treatment cycle.

Is this technology scalable for all of India?

Yes; the project serves as a model for full-scale deployment at other industrial refineries and facilities nationwide.

What are the primary advantages over other methods?

Phycoremediation is carbon-negative, uses minimal energy, employs no toxic chemicals, and is highly cost-efficient compared to traditional extraction or incineration.