As India advances toward its Net-Zero 2070 target, Green Hydrogen (GH2) has emerged as the cornerstone of the country’s Green Energy Transition. Unlike Grey or Blue hydrogen derived from fossil fuels, Green Hydrogen is produced through the electrolysis of water powered by renewable energy sources like solar and wind.

With the launch of the National Green Hydrogen Mission (NGHM), backed by an initial outlay of ₹19,744 crore, India is positioning itself as a global hub for the production, usage, and export of this clean fuel.

The Indian Landscape: Scaling Innovation

India’s journey is defined by a shift from lab-scale research to large-scale industrial application. Central to this mission is the Strategic Interventions for Green Hydrogen Transition (SIGHT) program, which provides financial incentives for electrolyser manufacturing and domestic GH2 production.

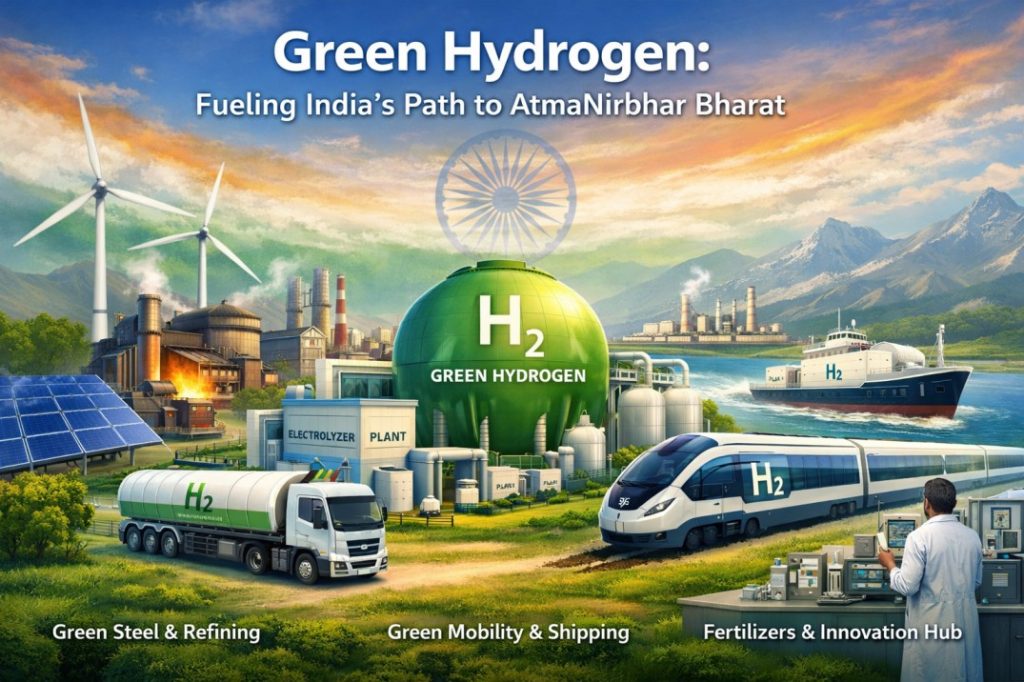

Currently, India’s strategic focus spans several hard-to-abate sectors:

Green Steel & Refining

Major industry players such as SAIL, JSW, and Tata Steel are conducting pilot trials for Direct Reduced Iron (DRI) using hydrogen. Meanwhile, IOCL and BPCL are integrating GH2 into refinery desulfurization processes.

Green Mobility & Shipping

India has launched dedicated hydrogen mobility corridors, featuring fuel cell electric vehicles (FCEVs). Indigenous success stories include the first hydrogen-powered inland waterway vessel, developed by Cochin Shipyard in collaboration with CSIR.

Fertilizers

The push for Green Ammonia aims to reduce India’s massive import dependency on natural gas, supporting the vision of an AtmaNirbhar Bharat.

DRIIV’s Role in the Ecosystem

Through the Delhi Science and Technology Cluster (DRIIV), the ecosystem is bridging the gap between academia and industry. By connecting IIT Delhi, CSIR labs, and startups, DRIIV facilitates deep-tech hardware validation and translational research.

Key focus areas include:

- Improving stack efficiency

- Developing indigenous PEM and Alkaline electrolysers

- Creating Hydrogen Valleys—integrated clusters where production and consumption co-exist to minimize logistics costs

With a target of 5 MMT (Million Metric Tonnes) annual production by 2030, the next decade will be defined by:

- Collaborative R&D

- Cost reduction (targeting $1/kg)

- Scaling sustainable technology solutions aligned with India’s affordability constraints

Frequently Asked Questions (FAQs)

What makes hydrogen “Green”?

It is produced using 100% renewable energy via electrolysis, resulting in zero carbon emissions during production.

What is the target of the National Green Hydrogen Mission?

The mission aims to achieve a production capacity of at least 5 million metric tonnes (MMT) per annum by 2030.

Which sectors in India will benefit most from Green Hydrogen?

Heavy industries like steel, refineries, chemical manufacturing, and long-haul heavy-duty transportation are the primary beneficiaries.

How does DRIIV support Green Hydrogen startups?

DRIIV provides a platform for industry-academia collaboration, pilot project implementation, and access to national testbeds for technology validation.

What is the SIGHT program?

It is a financial incentive mechanism under the NGHM designed to bolster domestic electrolyser manufacturing and green hydrogen production.